The Progressing Cavity Pump is well established as the pump of choice for handling abrasive solids. The wear optimization of the PC pumps is achieved through geometric design for minimum internal fluid velocities and by selecting proper speed & material grade of Rotor & Stator. Wear causes PC pump premature failure as a result of reduction in the volumetric efficiency. Wear compensation stator design allows to control and regulate the efficiency of Progressive Cavity Pumps for an extended period.

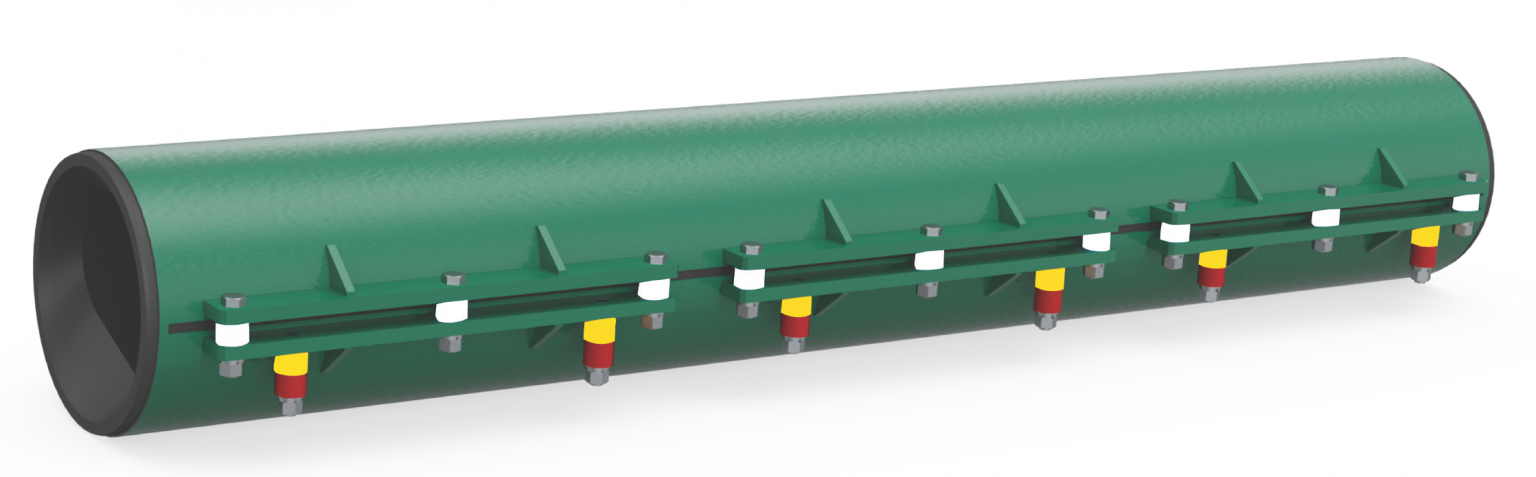

Excessive or un-regularized tightening in other design of adjustable stator lead to uneven or excessive interference, which may lead to fast wearing of the pumping elements (Stator & Rotor) or pump seizure and/or excessive power consumption. Roto’s unique wear compensation design uses spacers of predefined lengths to maintain almost even interface between the Rotor and Stator.

Assembly Procedure

Over a period of time, the stator wears out resulting in low flow & pressure. In that case, unscrew all nuts & remove spacers (White color), hex. head screws with washers. Insert spacers (Yellow color), hex. head screws with washers & tighten the nuts by applying equal torque.

After some time, the stator with Spacers (Yellow color) may again wear out & less flow and efficiency of pump may be observed. In that case, unscrew all nuts & remove spacers (Yellow color), hex. head screws with washers. Insert spacers (Red color), hex. Head screws with washers & tighten the nuts by applying equal torque to take care of wear compensation on stator. The wear compensation stator is supplied with 3 sets of inserts White, Yellow and Red.

White – Comes mounted on stator – Standard interference, no tightening required.

Yellow – First change after volumetric efficiency drops. Remove all white inserts and put yellow inserts and tighten all set

screws uniformly.

Red – Second and final change after volumetric efficiency drops further. Remove all yellow inserts and put red inserts and tighten all set screws.

This arrangement is available for Roto’s PCP models above M591 to 79M

Advantages

- Application for medium and large size pumps.

- Uniform interference maintained between pumping elements.

- Improved volumetric efficiency is archived by regulated adjustments.

- Wear compensation inserts supplied duly mounted on wear compensation stator.

- Easy to operate.